We all know that you can't have a cost-effective electric car without a cost-effective battery. We also know that a small but vocal hodgepodge of ideologues, activists, politicians and dreamers wants everyone to believe that rapid and stunning advances in lithium-ion batteries will finally make the dream a reality after a century of one abject failure after another.

I frequently caution readers that it won't be anywhere near as easy as the proponents claim.

In a new report titled "Searching for Innovations to Cut Li-ion Battery Costs" Lux Research did a yeoman's job dissecting lithium-ion battery mythology and putting the often inconsistent and invariably confusing world of battery cost claims into an understandable and comprehensive framework that:

- Explains the technical differences between various types of lithium-ion cells;

- Explains how future technological improvements will impact cell costs;

- Explains the differences between cell and battery pack costs;

- Explains the differences between nominal and useable pack capacity; and

- Reinforces the inconvenient but undeniable truths that:

- It's lithium-ion batteries or bust for plug-in vehicles;

- Battery costs will ultimately dictate the future of EVs;

- There isn't much hope for stunning cost reductions through the end of this decade, and

- Over the next eight years incremental solutions like micro-hybrids will be preferred by automakers and consumers alike because they provide reasonable fuel savings at a reasonable price.

Lux has created a formidable piece of work that's directed at industry professionals and institutional investors. While I can't do the report justice in a blog, I can at least touch on a few high points. For readers who'd like to learn more directly from the source, Lux will present a free webinar on Tuesday April 3rd at 11 a.m. EDT.

All lithium-ion batteries are not created equal. A critical but frequently misunderstood battery performance metric is the relationship between power and energy.

- Hybrid electric vehicles, or HEVs, are power applications that typically use a small (±1.4 kWh) battery pack to absorb braking energy for immediate re-use in the next acceleration cycle.

- Plug-in hybrid electric vehicles, or PHEVs, occupy the middle ground and use a mid-sized (5.2 to 16 kWh) battery pack to offer both hybrid and electric drive functions, which means they require both power and energy.

- Battery electric vehicles, or BEVs, are energy applications that use a massive (24 to 85 kWh) battery pack to propel vehicles for long distances at high speeds.

In general, HEV batteries cost more per kWh than PHEV batteries, which in turn cost more per kWh than BEV batteries. Likewise, smaller battery packs for short-range BEVs from Nissan (NSANY.PK) cost more per kWh than larger battery packs for long-range BEVs from Tesla Motors (TSLA).

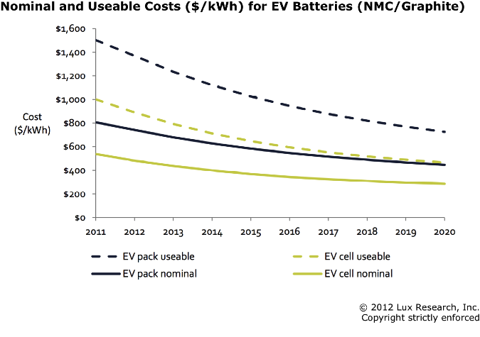

Nominal cost per kWh is far lower than effective cost per kWh of useable energy.

Most battery packs are designed with safety margins that reduce battery strain from operating a vehicle at a very high or a very low state of charge. Since nominal capacity is always higher than useful capacity, battery pack cost per kWh of useful energy is always higher than than nominal battery pack cost.

Nominal pack cost for PHEVs is currently about $800 per kWh, but the effective pack cost is closer to $1,500 per kWh of useable energy. By 2020, Lux expects nominal pack cost for PHEVs to decline to about $500 per kWh, but it believes effective pack cost will be closer to $800 per kWh of useable energy.

Nominal pack cost for BEVs is currently about $750 per kWh, but effective pack cost is closer to $1,400 per kWh of useable energy. By 2020, Lux expects nominal pack cost for BEVs to decline to about $400 per kWh, but it believes effective pack cost will be closer to $700 per kWh of useable energy.

The following graph from the Lux report shows how they expect nominal and useable costs of automotive cells and EV battery packs based on nickel, manganese and cobalt chemistry to evolve through the end of the decade. It can be particularly instructive for investors who've had a hard time visualizing the disparities between nominal cell and battery pack costs and effective useful energy storage capacity costs.

(Click to enlarge)

While the latest Lux forecasts for battery pack costs are significantly higher than most imagine based on press releases and news reports, they tie closely to comparable 2020 cost estimates from an AutomotiveWorld webinar last Thursday on "Reducing the cost of EV batteries." While neither organization focused on the fact that the price a battery manufacturer charges an automaker doesn't include the automaker's integration costs or markup, the fact remains that the effective 2020 cost to the consumer will be on the order of $1,000 per kWh of useful battery capacity.

HEVs are fuel efficiency technologies that squeeze as much mileage as possible from a gallon of gasoline. In contrast, PHEVs and BEVs are fuel substitution technologies that swap a battery pack for a fuel tank so that owners can swap electricity from coal and natural gas for gasoline. Advocates wax poetic on using alternative energy to charge EVs, but the truth is the virtue of green electrons lies in their creation, rather than their use, and most drivers want to use their cars during daylight hours, which is the only time solar panels work. While electric drive can be highly efficient in runabouts like the cute Renault Twizy, it can be preposterously wasteful in rubenesque halo cars like the Fisker Karma.

It's a mystery to me how EV advocates can steadfastly cling to their mythology in the face of caution from leaders like Energy Secretary Steven Chu who told participants in the November 2010 United Nations Climate Change Conference:

"And what would it take to be competitive? It will take a battery, first, that can last for 15 years of deep discharges; you need about five as a minimum, but really six- or seven-times higher storage capacity and you need to bring the price down by about a factor of three."

The Secretary's goals seem pretty straightforward:

- A 15 year life;

- Five to seven times higher storage capacity; and

- A two-thirds cost reduction.

Achieving those lofty goals is proving to be far more daunting than describing them.

Lux is currently forecasting a 50% reduction in battery costs over the next eight years in the most likely scenario, which works out to an aggressive but attainable improvement of five to six percent per year. A123 Systems (AONE) has not made significant visible progress in efforts to reduce manufacturing costs over the last three years. While Altair Nanotechnologies (ALTI) and Valence Technologies (VLNC) are a good deal more opaque than A123 Systems when it comes to providing reliable cost data to the SEC or the markets, they also seem to be having problems reducing their costs.

Investors who expect cost reduction curves like we've seen in electronics will be sorely disappointed. Investors who pay 17.5 times book value for a money losing start-up like Tesla when they could pay 6.3 times book value for an established and extraordinarily profitable innovator like Apple (AAPL) will pay dearly to learn an important lesson:

– That markets may act like a voting machine in the short term, but they always act like a weighing machine in the long term.

Disclosure: None.

===============================================

Plug-in hybrid

A plug-in hybrid electric vehicle (PHEV), also known as a plug-in hybrid, is a hybrid vehicle with rechargeable batteries that can be restored to full charge by connecting a

plug to an external electric power source. A PHEV shares the characteristics of both a conventional hybrid electric vehicle, having an electric motor and an internal combustion engine; and of an all-electric vehicle, also having a plug to connect to the electrical grid. Most PHEVs on the road today are passenger cars, but there are also PHEV versions of commercial vehicles and vans, utility trucks, buses, trains, motorcycles, scooters, and military vehicles.

The cost for electricity to power plug-in hybrids for all-electric operation has been estimated at less than one quarter of the cost of gasoline. Compared to conventional vehicles, PHEVs can reduce air pollution, dependence on petroleum and fossil fuels, and greenhouse gas emissions that contribute to global warming. PHEVs also eliminate the problem of "range anxiety" associated to all-electric vehicles, because the combustion engine works as a back up when the batteries are depleted. Plug-in hybrids use no fossil fuel during their all-electric range and produce lower greenhouse gas emissions if their batteries are charged from renewable electricity. Other benefits include improved national energy security, fewer fill-ups at the filling station, the convenience of home recharging, opportunities to provide emergency backup power in the home, and vehicle-to-grid (V2G) applications.

Chinese battery manufacturer and automaker BYD Auto released the F3DM PHEV-62 (PHEV-100 km) to the Chinese fleet market on December 15, 2008, for 149,800 yuan (US $22,000), and began sales to the general public in Shenzhen in March 2010. Toyota, General Motors, Ford, California startups Fisker Automotive and Aptera Motors, Volkswagen, Volvo, and Hyundai have scheduled the introduction of production PHEV automobiles. The PHEV-6 (PHEV-9.7 km) Toyota Prius will be offered beginning with commercial fleets in 2009. The luxury Fisker Karma PHEV-50 (PHEV-80 km) sports car is slated for late 2009, and GM's PHEV-40 (PHEV-64 km) Chevrolet Volt and the Volkswagen Golf PHEV-50 km plug-ins are expected in 2010. Ford's PHEV-30 Escape SUV is already being used in utility fleets, and due out to the general public in 2012.

Most PHEVs on the road in the US are conversions of conventional hybrid electric vehicles, and the most prominent PHEVs are conversions of 2004 or later Toyota Prius, which have had plug-in charging and more batteries added and their electric-only range extended. Several countries, including the United States and several European countries, have enacted laws to facilitate the introduction of PHEVs through tax credits, emissions mandates, and by financing research and development of advanced batteries and other related technologies. Introduction of PHEVs also benefits from laws and regulations enacted for hybrid vehicles.

Terminology

A plug-in hybrid's all-electric range is designated by PHEV-[miles] or PHEV[kilometers]km in which the number

Hybrids Plus plug-in hybrid Toyota Prius conversion with PHEV-30 (30 mile or 48 km all-electric range) battery packs |

represents the distance the vehicle can travel on battery power alone. For example, a PHEV-20 can travel twenty miles (32 km) without using its combustion engine, so it may also be designated as a PHEV32km.

The Energy Independence and Security Act of 2007 defines a plug-in electric drive vehicle as a vehicle that:

- draws motive power from a battery with a capacity of at least 4 kilowatt hours;

- can be recharged from an external source of electricity for motive power; and

- is a light-, medium-, or heavy-duty motor vehicle or nonroad vehicle.

This distinguishes PHEVs from regular hybrid cars mass marketed today, which do not use any electricity from the grid.

The Institute of Electrical and Electronics Engineers (IEEE) defines PHEVs similarly, but also requires that the hybrid electric vehicle can drive at least ten miles (16 km) in all-electric mode (PHEV-10; PHEV16km), while consuming no gasoline or diesel fuel.

The California Air Resources Board uses the term "off-vehicle charge capable" (OVCC) to mean having the capability to charge a battery from an off-vehicle electric energy source that cannot be connected or coupled to the vehicle in any manner while the vehicle is being driven.

Other popular terms sometimes used for plug-in hybrids are "grid-connected hybrids", "Gas-Optional Hybrid Electric Vehicle" (GO-HEV) or simply "gas-optional hybrids". General Motors is calling its Chevrolet Volt series plug-in hybrid a "Extended-Range Electric Vehicle."

History

Hybrid vehicles were produced as early as 1899 by Lohner-Porsche. Early hybrids could be charged from an external source before operation. However, the term "plug-in hybrid" has come to mean a hybrid vehicle that can be charged from a standard electrical wall socket. The July 1969 issue of Popular Science featured an article on the General Motors XP-883 plug-in hybrid. The concept commuter vehicle housed six 12-volt lead-acid batteries in the trunk area and a transverse-mounted DC electric motor turning a front-wheel drive. The car could be plugged into a standard North American 120 volt AC outlet for recharging.

Lithium-ion battery pack, with cover removed, in a CalCars "PRIUS+" plug-in hybrid converted Toyota Prius converted by EnergyCS. |  |

In 2003, Renault began selling the Elect'road, a plug-in series hybrid version of their popular Kangoo, in Europe. It was sold alongside Renault's "Electri'cité" electric-drive Kangoo battery electric van. The Elect'road had a 150 km (93 mi) range using a nickel-cadmium battery pack and a 500 cc (31 cu in), 16 kilowatt liquid-cooled gasoline "range-extender" engine. It powered two high voltage/high output/low volume alternators, each of which supplied up to 5.5 kW at 132 volts at 5000 rpm. The operating speed of the internal combustion engine—and therefore the output delivered by the generators—varied according to demand. The fuel tank had a capacity of 10 liters (2.6 U.S. gal; 2.2 imp gal) and was housed within the right rear wheel arch. The range extender function was activated by a switch on the dashboard. The on-board 3.5 kilowatt charger could charge a depleted battery pack to 95% charge in about four hours from a 240 volts supply. Passenger compartment heating was powered by the battery pack as well as an auxiliary coolant circuit that was supplied by the range extender engine. After selling about 500 vehicles, primarily in France, Norway and the UK, at a price of about €25,000, the Elect'road was redesigned in 2007.

In September 2004, CalCars converted a 2004 Toyota Prius into a prototype of what it called the PRIUS+. With the addition of 130 kg (300 lb) of lead-acid batteries, the PRIUS+ achieved roughly double the fuel economy of a standard Prius and could make trips of up to 15 km (9 mi) using only electric power. The vehicle, which is owned by CalCars technical lead Ron Gremban, is used in daily driving, as well as a test bed for various improvements to the system.

On July 18, 2006, Toyota announced that it "plans to develop a hybrid vehicle that will run locally on batteries charged by a household electrical outlet before switching over to a gasoline engine for longer hauls." Toyota has said it plans to migrate to lithium-ion batteries in future hybrid models, but not in the next-generation Prius, expected in fall 2008. Lithium-ion batteries are expected to significantly improve fuel economy, and have a higher energy-to-weight ratio, but cost more to produce, and raise safety concerns due to high operating temperatures.

On November 29, 2006, GM announced plans to introduce a production plug-in hybrid version of Saturn's Greenline Vue SUV with an all-electric range of 10 mi (16 km). The model's sale is anticipated by fall 2009, and GM announced in January 2007 that contracts had been awarded to two companies to design and test lithium-ion batteries for the vehicle. GM has said that they plan on introducing plug-in and other hybrids "for the next several years".

In January 2007, GM unveiled the Chevrolet Volt, which is expected to initially feature a plug-in capable, battery-dominant series hybrid architecture which they are calling E-Flex. Future E-Flex plug-in hybrid vehicles may use gasoline, diesel, or hydrogen fuel cell power to supplement the vehicle's battery. General Motors envisions an eventual progression of E-Flex vehicles from plug-in hybrids to pure electric vehicles, as battery technology improves. General Motors presented the Volt as a PHEV-40 that starts its engine when 40% of the battery charge remains, and which can achieve a fuel economy of 50 mpg-U.S. (4.7 L/100 km; 60 mpg-imp), even if the vehicle's batteries are not charged.

On July 25, Japan's Ministry of Land, Infrastructure and Transport certified Toyota's plug-in hybrid for use on public roads, making it the first automobile to attain such approval. Toyota plans to conduct road tests to verify its all-electric range. The plug-in Prius was said to have an all-electric range of 13 km (8 mi). But later prototypes shown at the 2008 Paris Auto Show had an electric-only range of "just a little over six miles."

On August 9, 2007, General Motors vice-president Robert Lutz announced that GM is on track for Chevrolet Volt road testing in 2008 and production to begin by 2010. Announcing an agreement with A123Systems, Lutz said GM would like to have their planned Saturn Vue plug-in on the roads by 2009. The Volt has an all-electric range of 40 mi (64 km). On September 5, Quantum Technologies and Fisker Coachbuild, LLC announced the launch of a joint venture in Fisker Automotive. Fisker intends to build a US$80,000 luxury PHEV-50, the Fisker Karma, anticipated in late 2009. In September, Aptera Motors announced their Typ-1 two-seater. They plan to produce both an electric 2e and a plug-in series hybrid 2h with a common three-wheeled, composite body design. As of 2009, over two thousand hybrid pre-orders have been accepted, and production of the hybrid configuration is expected to begin in 2010.

On October 9, 2007, Chinese manufacturer BYD Automobile Company (which is owned by China's largest mobile phone battery maker) announced that it would be introducing a production PHEV-60 sedan in China in the second half of 2008. BYD exhibited it January 2008 at the North American International Auto Show in Detroit. Based on BYD's midsize F6 sedan, it uses lithium iron phosphate (LiFeP04)-based batteries instead of lithium-ion, and can be recharged to 70% of capacity in just 10 minutes.

On December 2007 Ford delivered the first Ford Escape Plug-in Hybrid of a fleet of 20 demonstration PHEVs to Southern California Edison. As part of this demonstration program Ford also developed the first ever flexible-fuel plug-in hybrid SUV, which was delivered in June 2008. This demonstration fleet of plug-ins has been in field testing with utility company fleets in the U.S. and Canada, and during the first two years since the program began, the fleet has logged more than 75,000 miles. On August 2009 Ford delivered the first Escape Plug-in equipped with intelligent vehicle-to-grid (V2G) communications and control system technology, and Ford plans to equip all 21 plug-in hybrid Escapes with the vehicle-to-grid communications technology. Sales of the Escape PHEV are scheduled for 2012.

In January 2008, a privately-run waiting list to purchase the Chevy Volt reached 10,000 members. The list, administered by Lyle Dennis, was started one year prior. Dr. Yi Cui and colleagues at Stanford University's Department of Materials Science and Engineering have discovered that silicon nanowires give rechargeable lithium ion batteries 10 times more charge. On January 7, Bob Lutz, the Vice Chairman of General Motors said, "The electrification of the automobile is inevitable." On January 14, Toyota announced they would start sales of lithium-ion battery PHEVs by 2010, but later in the year Toyota indicated they would be offered to commercial fleets in 2009.

On March 27, the California Air Resources Board modified their regulations, requiring automobile manufacturers to produce 58,000 plug-in hybrids during 2012 through 2014. This requirement is an asked-for alternative to an earlier mandate to produce 25,000 pure zero-emissions vehicles, reducing that requirement to 5,000. On June 26, Volkswagen announced that they would be introducing production plug-ins based on the Golf compact. Volkswagen uses the term 'TwinDrive' to denote a PHEV. In September, Mazda was reported to be planning PHEVs. On September 23, Chrysler announced that they had prototyped a plug-in Jeep Wrangler and a Chrysler Town and Country mini-van, both PHEV-40s with series powertrains, and an all-electric Dodge sports car, and said that one of the three vehicles would go in to production.

On October 3, the U.S. enacted the Energy Improvement and Extension Act of 2008. The legislation provided tax credits for the purchase of plug-in electric vehicles of battery capacity over 4 kilowatt-hours. The federal tax credits were extended and modified by the American Clean Energy and Security Act of 2009, but now the battery capacity must be over 5 Kwh and the credit phases out after the automaker has sold at least 200,000 vehicles in the U.S.

On December 15, 2008 BYD Auto began selling its F3DM PHEV-60 in China, becoming the first production plug-in hybrid sold in the world, though initially was available only for corporate and government customers. Sales to the general public began in Shenzhen in March 2010, but because the F3DM nearly doubles the price of cars that run on conventional fuel, BYD expects subsidies from the local government to make the plug-in affordable to personal buyers.

Powertrains

PHEVs are based on the same three basic powertrain architectures as conventional electric hybrids:

Series hybrids use an internal combustion engine (ICE) to

The Chevrolet Volt car is a series plug-in hybrid, meaning that its gasoline engine power is exclusively used to generate electricity and not used directly for drive wheel propulsion. |

turn a generator, which in turn supplies current to an electric motor, which then rotates the vehicle’s drive wheels. A battery or supercapacitor pack, or a combination of the two, can be used to store excess charge. Examples of series hybrids include the Renault Kangoo Elect'Road, Toyota's Japan-only Coaster light-duty passenger bus, Daimler AG's hybrid Orion bus, the Chevrolet Volt production car, the Opel Flextreme concept car, and many diesel-electric locomotives. With an appropriate balance of components this type can operate over a substantial distance with its full range of power without engaging the ICE. As is the case for other architectures, series hybrids can operate without recharging as long as there is liquid fuel in the tank.

Parallel hybrids, such as Honda's Insight, Civic, and Accord hybrids, can simultaneously transmit power to their drive wheels from two distinct sources—for example, an internal combustion engine and a battery-powered electric drive. Although most parallel hybrids incorporate an electric motor between the vehicle's engine and transmission, a parallel hybrid can also use its engine to drive one of the vehicle's axles, while its electric motor drives the other axle and/or a generator used for recharging the batteries. (This type is called a road-coupled hybrid). The Audi Duo plug-in hybrid concept car is an example of this type of parallel hybrid architecture. Parallel hybrids can be programmed to use the electric motor to substitute for the ICE at lower power demands as well as to substantially increase the power available to a smaller ICE, both of which substantially increase fuel economy compared to a simple ICE vehicle.

Series-parallel hybrids have the flexibility to operate in either series or parallel mode. Hybrid powertrains currently used by Ford, Lexus, Nissan, and Toyota, which some refer to as “series-parallel with power-split,” can operate in both series and parallel mode at the same time. As of 2007, most plug-in hybrid conversions of conventional hybrids utilize this architecture.

Modes of operation

Regardless of its architecture, a plug-in hybrid may be capable of charge-depleting and charge-sustaining modes. Combinations of these two modes are termed blended mode or mixed-mode. These vehicles can be designed to drive for an extended range in all-electric mode, either at low speeds only or at all speeds. These modes manage the vehicle's battery discharge strategy, and their use has a direct effect on the size and type of battery required:

Charge-depleting mode allows a fully charged PHEV to operate exclusively (or depending on the vehicle, almost exclusively, except during hard acceleration) on electric power until its battery state of charge is depleted to a predetermined level, at which time the vehicle's internal combustion engine or fuel cell will be engaged. This period is the vehicle's all-electric range. This is the only mode that a battery electric vehicle can operate in, hence their limited range.

Blended mode is a kind of charge-depleting mode. It is

|

normally employed by vehicles which do not have enough electric power to sustain high speeds without the help of the internal combustion portion of the powertrain. A blended control strategy typically increases the distance from stored grid electricity compared to a charge-depleting strategy. The Renault Kangoo and some Toyota Prius conversions are examples of vehicles that use this mode of operation. The Electri'cité and Elect'road versions of the Kangoo were charge-depleting battery electric vehicles: the Elect'road had a modest internal combustion engine which extended its range somewhat. Conversions of 2004 and later model Toyota Prius can only run without using the ICE at speeds of less than about 42 mph (68 km/h) due to the limits dictated by the vehicle's powertrain control software. However, at faster speeds electric power can still be used to displace gasoline, thus improving the fuel economy in blended mode and generally doubling the fuel efficiency.

Charge-sustaining mode is used by production hybrid vehicles (HEVs) today, and combines the operation of the vehicle's two power sources in such a manner that the vehicle is operating as efficiently as possible without allowing the battery state of charge to move outside a predetermined narrow band. Over the course of a trip in a HEV the state of charge may fluctuate but will have no net change. The battery in a HEV can thus be thought of as an energy accumulator rather than a fuel storage device. Once a plug-in hybrid has exhausted its all-electric range in charge-depleting mode, it can switch into charge-sustaining mode automatically.

Mixed mode describes a trip in which a combination of the above modes are utilized. For example, a PHEV-20 Prius conversion may begin a trip with 5 miles (8 km) of low speed charge-depleting, then get onto a freeway and operate in blended mode for 20 miles (32 km), using 10 miles (16 km) worth of all-electric range at twice the fuel economy. Finally the driver might exit the freeway and drive for another 5 miles (8 km) without the internal combustion engine until the full 20 miles (32 km) of all-electric range are exhausted. At this point the vehicle can revert back to a charge sustaining-mode for another 10 miles (16 km) until the final destination is reached. Such a trip would be considered a mixed mode, as multiple modes are employed in one trip. This contrasts with a charge-depleting trip which would be driven within the limits of a PHEV's all-electric range. Conversely, the portion of a trip which extends beyond the all-electric range of a PHEV would be driven primarily in charge-sustaining mode, as used by a conventional hybrid.

Electric power storage

PHEVs typically require deeper battery charging and discharging cycles than conventional hybrids. Because the number of full cycles influences battery life, this may be less than in traditional HEVs which do not deplete their batteries as fully. However, some authors argue that PHEVs will soon become standard in the automobile industry. Design issues and trade-offs against battery life, capacity, heat dissipation, weight, costs, and safety need to be solved. Advanced battery technology is under development, promising greater energy densities by both mass and volume, and battery life expectancy is expected to increase.

The cathodes of some early 2007 lithium-ion batteries are made from lithium-cobalt metal oxide. This material is expensive, and cells made with it can release oxygen if overcharged. If the cobalt is replaced with iron phosphates, the cells will not burn or release oxygen under any charge. The price premium for early 2007 conventional hybrids is about US$5000, some US$3000 of which is for their NiMH battery packs. At early 2007 gasoline and electricity prices, that would mean a break-even point after six to ten years of operation. The conventional hybrid premium could fall to US$2000 in five years, with US$1200 or more of that being cost of lithium-ion batteries, providing for a three-year payback. The payback period may be longer for plug-in hybrids, because of their larger, more expensive batteries.

Nickel-metal hydride and lithium-ion batteries can be recycled; Toyota, for example, has a recycling program in place under which dealers are paid a US$200 credit for each battery returned. However, plug-in hybrids typically use larger battery packs than comparable conventional hybrids, and thus require more resources. Pacific Gas and Electric Company (PG&E) has suggested that utilities could purchase used batteries for backup and load leveling purposes. They state that while these used batteries may be no longer usable in vehicles, their residual capacity still has significant value. More recently, General Motors (GM) has said it has been "approached by utilities interested in using recycled Volt batteries as a power storage system, a secondary market that could bring down the cost of the Volt and other plug-in vehicles for consumers."

Lithium iron phosphate (LiMPO4) is a class of cathode materials used in lithium iron phosphate batteries that is getting attention from the auto industry. Valence Technologies produce a lithium iron manganese phosphate (LiFeMgPO4) battery. with LG Chem selling lithium iron phospate (LiFePO4) batteries for the Chevy Volt and A123 producing a lithium nano-phosphate battery The most important merit of this battery type is safety and high-power. Lithium iron phosphate batteries are one of three major types in LFP family, the other two being nano-phosphate and nano-cocrystalline-olivine.

In France, Électricité de France (EDF) and Toyota are installing charging stations for PHEVs on roads, streets and parking lots. EDF is also partnering with Elektromotive, Ltd. to install 250 new charging points over six months from October 2007 in London and elsewhere in the UK. Recharging points also can be installed for specific uses, as in taxicab stands. Project Better Place began in October 2007 and is working with Renault on development of exchangeable batteries (battery swapping).

Ultracapacitors (or "supercapacitors") are used in some plug-in hybrids, such as AFS Trinity's concept prototype, to store rapidly available energy with their high power density, in order to keep batteries within safe resistive heating limits and extend battery life. The UltraBattery combines a supercapacitor and a battery in a single unit, creating a hybrid car battery that lasts longer, costs less and is more powerful than current technologies used in plug-in hybrid electric vehicles (PHEVs).

The optimum battery size varies depending on whether the aim is to reduce oil consumption, running costs, or emissions, but a recent study concluded that "The best choice of PHEV battery capacity depends critically on the distance that the vehicle will be driven between charges. Our results suggest that for urban driving conditions and frequent charges every 10 miles or less, a low-capacity PHEV sized with an AER (all electric range) of about 7 miles would be a robust choice for minimizing gasoline consumption, cost, and greenhouse gas emissions. For less frequent charging, every 20–100 miles, PHEVs release fewer GHGs, but HEVs are more cost effective. "

Conversions of production vehicles

Further information: Electric vehicle conversion

Conversion of fossil-fuel vehicles

Retrofit electrification requires only one-fifth the energy required to build a new vehicle. This is called ACEV-to-PHEV conversion. There are several companies that are converting fossil fuel non-hybrid vehicles (also called all-combustion engine vehicles) to plug-in hybrids:

- ConVerdant Vehicles (New Hampshire)

- Efficient Drivetrains Inc (California)

- Electradrive (California)

- EV Power Systems (North Carolina)

- H-Line Conversions (Kansas)

- Hybrid Electric Vehicle Technologies (Illinois)

- Linc Volt (California)

- Partnerships One (New Jersey)

- Poulsen Hybrid (Connecticut)

- Rapid Electric Vehicles (Vancouver)

- Re-Involt Hybrid Conversions (N. Carolina)

Colorado is going to offer $6,000 credit for PHEV conversions (in addition to a federal 10% credit up to $4,000 for qualifying vehicles).

Conversions of gas-only hybrids

Aftermarket conversion of an existing production hybrid (a charge-maintaining hybrid) to a plug-in hybrid (called CHEV-to-

15 lead-acid batteries, PFC charger, and regulators installed into WhiteBird, a PHEV-10 conversion of a Toyota Prius |

PHEV conversion) typically involves increasing the capacity of the vehicle's battery pack and adding an on-board AC-to-DC charger. Ideally, the vehicle's powertrain software would be reprogrammed to make full use of the battery pack's additional energy storage capacity and power output.

Many early plug-in hybrid electric vehicle conversions have been based on the 2004 or later model Toyota Prius. Some of the systems have involved replacement of the vehicle's original NiMH battery pack and its electronic control unit. Others, such as A123 Hymotion, the CalCars Prius+, and the PiPrius, piggyback an additional battery back onto the original battery pack, this is also referred to as Battery Range Extender Modules (BREMs). Within the electric vehicle conversion community this has been referred to as a "hybrid battery pack configuration". Early lead-acid battery conversions by CalCars demonstrated 10 miles (15 km) of EV-only and 20 miles (30 km) of double mileage blended mode range.

EDrive Systems use Valence Technology Li-ion batteries and have a claimed 40 to 50 miles (64 to 80 km) of electric range. Other companies offering plug-in conversions or kits for the Toyota Prius (some of them also for Ford Escape Hybrid) include Hymotion, Hybrids Plus Manzanita Micro and OEMtek BREEZ (PHEV-30). AFS Trinity's XH-150 claims that it has created a functioning plug-in hybrid with a 40 miles (64 km) all-electric range and that it has solved the overheating problem that rapid acceleration can cause in PHEVs and extend battery life.

The EAA-PHEV project was conceived by CalCars and the Electric Auto Association in October 2005 to accelerate efforts to document existing HEVs and their potential for conversion into PHEVs. It includes a "conversion interest" page. The Electric Auto Association-PHEV "Do-It-Yourself" Open Source community's primary focus is to provide conversion instructions to help guide experienced converters through the process, and to provide a common design that could demonstrate multiple battery technologies. Many members of organizations such as CalCars and the EAA as well as companies like Hybrids Plus, Hybrid Interfaces of Canada, and Manzanita Micro participate in the development of the project.

Plug-In Supply, Inc. of Petaluma, California offers components and assemblies to build the Prius+, the plug-in conversion invented by CalCars. Their lead-acid battery box assembly forms a complete install package, providing access to the spare tire and containing twenty 12 volt lead-acid batteries and all high voltage components and control electronics. The "PbA Battery Box Assembly" is also available without batteries. It provides about 10 miles (16 km) of EV mode range. Conversion time was reduced by plug-in supply to one day.

Oemtek offers a Valence powered lithium iron phosphate conversion that should provide 50 miles (80 km) of all-electric range. The Motor Industry Research Association has announced a retrofit hybrid conversion kit that provides removable battery packs that plug into a wall outlet for charging. Poulsen Hybrid is developing a conversion kit that will add through-the-road plug-in hybrid capability to conventional vehicles by externally mounting electric motors onto two of the wheels.

AutomationTech, Inc. of Troy, Michigan offers universal plugin conversion kits with components and assemblies to build two stage hybrid battery system invented by AutomatonTech Inc. Their lithium-ion battery box assembly forms a complete install package, providing access to the spare tire and containing 16/32 lithium phosphate battery cells, a DC/DC converter and a charger. It provides about 10 miles (16 km) of EV mode range for under $2000 (2 kW·h model). Longer range 4 kW·h model is also available for $1000 more. Conversion time was reduced to two/three hours.

Amberjac Projects, a UK company based in Grantham, Lincolnshire makes conversions for the European Union, based on EDrive Systems emerged from the original EnergyCS

Advantages

Energy resilience and petroleum displacement

Each kilowatt hour of battery capacity in use will displace up to 50 US gallons (190 l; 42 imp gal) of petroleum fuels per year (gasoline or diesel fuels). Also, electricity is multi-sourced and, as a result, it gives the greatest degree of energy resilience.

Fuel efficiency

Claimed fuel economy for PHEVs depends on the amount of driving between recharges. If no gasoline is used the MPG equivalent depends only on the efficiency of the electric system. A 120 km (70 mi) range PHEV-70 may annually require only about 25% as much gasoline as a similarly designed PHEV-0, depending on how it will be driven and the trips for which it will be used. The furthest all-electric range in a PHEV planned for mass production is the PHEV-60 BYD F6e.

A further advantage of PHEVs is that they have potential to be even more efficient than conventional hybrids because a more limited use of the PHEV's internal combustion engine may allow the engine to be used at closer to its maximum efficiency. While a Prius is likely to convert fuel to motive energy on average at about 30% efficiency (well below the engine's 38% peak efficiency) the engine of a PHEV-70 would be likely to operate far more often near its peak efficiency because the batteries can serve the modest power needs at times when the combustion engine would be forced to run well below its peak efficiency. The actual efficiency achieved depends on losses from electricity generation, inversion, battery charging/discharging, the motor controller and motor itself, the way a vehicle is used (its duty cycle), and the opportunities to recharge by connecting to the electrical grid.

The Society of Automotive Engineers (SAE) developed their recommended practice in 1999 for testing and reporting the fuel economy of hybrid vehicles and included language to address PHEVs. An SAE committee is currently working to review procedures for testing and reporting the fuel economy of PHEVs. The Toronto Atmospheric Fund tested ten retrofitted plug-in hybrid vehicles that achieved an average of 5.8 litres per 100 kilometre or 40.6 miles per gallon over six months in 2008, which was considered below the technology's potential.

In "real world" testing using normal drivers, some Prius PHEV conversions may not achieve much better fuel economy than HEVs. For example, a plug-in Prius fleet, each with a 30 miles (48 km) all-electric range, averaged only 51 mpg-U.S. (4.6 L/100 km; 61 mpg-imp) in a 17,000-mile (27,000 km) test in Seattle, and similar results with the same kind of conversion battery models at Google.org. Moreover, the additional battery pack costs $10,000–11,000.

Greenhouse gas emissions

There has been much debate over the potential GHG emissions reductions that can be achieved with PHEV. A study by the Electric Power Research Institute reports on page 80 that a 338 TW·h or 5.8% increase in power generation needed as a result of PHEV. In the same report they also state that CO2 emissions could increase by 430 million metric tons in Table 3-15 on page 87. The article concludes:

- "In summary, the addition of PHEVs as a significant transportation option adds approximately 6% to the total national electricity demand in 2030 compared to the base case with no PHEVs. Due to the charging profile that results in most of this additional demand occurring during off-peak hours (late night/early morning) there is an increase in the need for baseload generation. The addition of coal-fired generation to meet this need for more baseload generation does not result in any significant differences in annual emissions of SO2, NOx and Hg because of the caps on those pollutants. Therefore, any reductions in emissions of SO2, NOx or Hg from non-electric generating sources would result in a net national decline in these emissions. However, it does result in an appreciable increase in CO2 and PM emissions as this analysis has not assumed any limits on CO2 or PM emissions."

Another advantage of PHEV adoption is the potential reduction in carbon emissions. Increased drivetrain efficiency results in significant reduction of greenhouse gas emissions, even taking into account energy lost to inefficiency in the production and distribution of grid power and charging of batteries. A study by the American Council for an Energy Efficient Economy (ACEEE) predicts that, on average, a typical American driver is expected to achieve about a 15% reduction in net CO2 emissions compared to the driver of a regular hybrid, based on the 2005 distribution of power sources feeding the US electrical grid. The ACEEE study also predicts that in areas where more than 80% of grid-power comes from coal-burning power plants, local net CO2 emissions will increase, while for PHEVs recharged in areas where the grid is fed by power sources with lower CO2 emissions than the current average, net CO2 emissions associated with PHEVs will decrease correspondingly.

A late 2008 study at Duke University suggests that for PHEV's to reduce greenhouse gas emissions more than hybrids a carbon pricing signal that encourages the development of low carbon power is needed. RAND also in 2008 studied the questions of a carbon tax, carbon cap and trade systems, increasing gasoline tax, and providing renewable energy subsidies under various economic conditions and vehicle type availabilities. RAND found that subsidies were able to provide a smoother transition to new energy sources, especially in the face of energy source price volatility, because subsidies can be structured according to relative costs between renewables and fossil fuel, while taxes and carbon trading schemes alone do not take relative prices of energy into account.

A large-scale June 2007 joint study by the Electric Power Research Institute (EPRI) and the Natural Resources Defense Council (NRDC) similarly found that the introduction of PHEVs into America’s consumer vehicle fleet could achieve significant greenhouse gas emission reductions. The EPRI-NRDC report estimates that, between 2010 and 2050, a shift toward PHEV use could reduce GHG emissions by 3.4 to 10.4 billion metric tons. The magnitude of these reductions would ultimately depend on the level of PHEV market penetration and the carbon intensity of the US electricity sector. In general, PHEVs can be viewed as an element in the "Pacala and Socolow wedges" approach which shows a way to stabilize CO2 emissions using a portfolio of existing techniques, including efficient vehicles.

GM Vice Chairman Bob Lutz has said the Chevy Volt will emit 40 grams of carbon dioxide per kilometer. That is well below the proposed European Union emission standards of 120–130 g/km.

Martin Eberhard, who co-founded pure electric vehicle maker Tesla Motors, says "if you do the math, you'll find that an electric car, even if you use coal to make electricity, produces less pollution per mile than burning gasoline in the best gasoline-powered car." The Minnesota Pollution Control Agency found that if Minnesota's fleet of vehicles making lengthy trips were replaced by plug-in hybrids, CO2 emissions per vehicle would likely decrease. However, unless more than 40% of the electricity used to charge the vehicles were to come from non-polluting sources, replacing the vehicles with non plug-in hybrids would engender a larger decrease in CO2 emissions. Plug-in hybrids use less fuel in all cases, and produce much less carbon dioxide in short commuter trips, which is how most vehicles are used. The difference is such that overall carbon emissions would decrease if all internal combustion vehicles were converted to plug-ins.

Researchers at Argonne National Laboratory adapted their GREET model to conduct a full well-to-wheels (WTW) analysis of energy use and greenhouse gas (GHG) emissions of plug-in hybrid electric vehicles for several scenarios, considering different on-board fuels and different sources of electricity generation for recharging the vehicle batteries. Three US regions were selected for the analysis, California, New York, and Illinois, as these regions include major metropolitan areas with significant vaiations in their energy generation mixes. The full cycle analysis results were also reported for the US generation mix and renewable electricity to examine cases of average and clean mixes, respectively This 2009 study showed a wide spread of energy balance and GHG emissions among the different fuel production technologies and grid generation mixes. The following table summarizes the main results:

| PHEV well-to-wheels energy use and greenhouse gas emissions for an all-electric range between 10 and 40 miles (16 and 64 km) with different on-board fuels.(1) (as a % relative to an internal combustion engine vehicle that uses gasoline) | |||||

|---|---|---|---|---|---|

| Analysis | Reformulated gasoline and Ultra-low sulfur diesel | E85 fuel from corn and switchgrass | Fuel cell hydrogen | ||

| Energy use reduction | 40–60% | 70–90% | more than 90% | ||

| GHG emissions reduction(2) | 30–60% | 40–80% | 10–100% | ||

| Source: Center for Transportation Research, Argonne National Laboratory (2009). See Table 1. Notes: (1) Simulations for year 2020 with PHEV model year 2015. (2) No direct or indirect land use changes included in the WTW analysis for bio-mass fuel feedstocks. | |||||

The Argonne study found that PHEVs offered reductions in petroleum energy use as compared with regular hybrid electric vehicles. More petroleum energy savings and also more GHG emissions reductions were realized as the all-electric range increased, except when electricity used to recharged was dominated by coal or oil-fired power generation. As expected, electricity from renewable sources realized the largest reductions in petroleum energy use and GHG emissions for all PHEVs as the all-electric range increased. The study also concluded that plug-in vehicles that employ biomass-based fuels (biomass-E85 and -hydrogen) may not realize GHG emissions benefits over regular hybrids if power generation is dominated by fossil sources.

Operating costs

A 2006 research estimate in California found that the operating costs of plug-ins charged at night was equivalent to 75¢ US per US gallon (20¢/L) of gasoline. The cost of electricity for a Prius PHEV is about US$0.03 per mile (US$0.019 per km), based on 0.26 kilowatt-hours per mile (0.16 kW·h/km; 0.58 MJ/km) and a cost of electricity of US$0.10 per kilowatt hour. During 2008, government and industry researchers tried to determine the optimum all-electric range.

Range anxiety elimination

One of the main barriers for the general adoption of all-electric cars is the "range anxiety" factor, the driver's fear of being stranded by a depleted battery before reaching the final destination. Plug-ins eliminate the range anxiety concerns because the gasoline engine serves as a back-up to recharge the battery and/or can provide propulsion directly. In the case of the Chevrolet Volt, its internal combustion engine generates electricity to power the electric engine responsible for the vehicle's propulsion, thus, access to a regular fuel station guarantees similar driving ranges as conventional gasoline-powered automobile.

Smog

The Ontario Medical Association announced that smog is responsible for an estimated 9,500 premature deaths in its province every year. Plug-in hybrids in emission-free electric mode may contribute to the reduction of smog.

Vehicle-to-grid electricity

PHEVs and fully electric cars may allow for more efficient use of existing electric production capacity, much of which sits idle as operating reserve most of the time. This assumes that vehicles are charged primarily during off peak periods (i.e., at night), or equipped with technology to shut off charging during periods of peak demand. Another advantage of a plug-in vehicle is their potential ability to load balance or help the grid during peak loads. This is accomplished with vehicle-to-grid technology. By using excess battery capacity to send power back into the grid and then recharge during off peak times using cheaper power, such vehicles are actually advantageous to utilities as well as their owners. Even if such vehicles just led to an increase in the use of night time electricity they would even out electricity demand which is typically higher in the day time, and provide a greater return on capital for electricity infrastructure.

In October 2005, five Toyota engineers and one Asian AW engineer published an IEEE technical paper detailing a Toyota-approved project to add vehicle-to-grid capability to a Toyota Prius. Although the technical paper described "a method for generating voltage between respective lines of neutral points in the generator and motor of the THS-II (Toyota Hybrid System) to add a function for generating electricity", it did not state whether or not the experimental vehicle could be charged through the circuit, as well. However, the vehicle was featured in a Toyota Dream House, and a brochure for the exhibit stated that "the house can supply electricity to the battery packs of the vehicles via the stand in the middle of the garage", indicating that the vehicle may have been a plug-in hybrid.

In November 2005, more than 50 leaders from public power utility companies across the United States met at the Los Angeles Department of Water and Power headquarters to

U.S. President Barack Obama examines hybrid vehicles in the Edison Electric Vehicle Technical Center in Pomona, California. |

discuss plug-in hybrid and vehicle-to-grid technology. The event, which was sponsored by the American Public Power Association, also provided an opportunity for association members to plan strategies that public power utility companies could use to promote plug-in hybrid technology. Greg Hanssen and Peter Nortman of EnergyCS and EDrive attended the two-day session, and during a break in the proceedings, made an impromptu display in the LADWP parking lot of their converted Prius plug-in hybrid.

In September 2006, the California Air Resources Board held a Zero Emission Vehicle symposium that included several presentations on V2G technology. In April 2007, Pacific Gas and Electric Company showcased a PHEV at the Silicon Valley Leadership Alternative Energy Solutions Summit with vehicle-to-grid capability, and demonstrated that it could be used as a source of emergency home power in the event of an electrical power failure. Regulations intended to protect electricians against power other than from grid sources would need to be changed, or regulations requiring consumers to disconnect from the grid when connected to non-grid sources will be required before such backup power solutions would be feasible.

Federal Energy Regulatory Commissioner Jon Wellinghoff coined the term "Cash-Back Hybrids" to describe payments to car owners for putting their batteries on the power grid. Batteries could also be offered in low-cost leasing or renting or by donation (including maintenance) to the car owners by the public utilities, in a vehicle-to-grid agreement.

Disadvantages

Cost of batteries

Disadvantages of plug-in hybrids include the additional cost, weight, and size of a larger battery pack. According to a 2010 study by the National Research Council, the cost of a lithium-ion battery pack is about USD 1,700/kW·h of usable energy, and considering that a PHEV-10 requires about 2.0 kW·h and a PHEV-40 about 8 kW·h, the manufacturer cost of the battery pack for a PHEV-10 is around USD 3,000 and it goes up to USD 14,000 for a PHEV-40. According to the same study, even though costs are expected to decline by 35% by 2020, market penetration is expected to be slow and therefore PHEVs are not expect to significantly impact oil consumption or carbon emissions before 2030, unless a fundamental breakthrough in battery technology occurs.

According to the 2010 NCR study, despite the fact that a mile driven on electricity is cheaper than one driven on gasoline, lifetime fuel savings are not enough to offset plug-ins high upfront costs, and it will take decades before the break even point is achieve. Furthermore, hundreds of billions of dollars in government subsidies and incentives are likely to be required to achieve rapid plug-in market penetration in the U.S.

Lithium iron phosphate batteries from Valence Technologies were used in the first plug-in hybrids from CalCars are providing a conversion for the Toyota Prius priced at $12,000. Hymotion also offers a conversion for $10,000 US but their conversion is only 5 kW where Oemtek's is 9 kW.

Recharging outside home garages

Many people have assumed that plug-in recharging will take place overnight at home. However, residents of cities, apartments, dormitories, and townhouses do not have garages or driveways with available power outlets, and they might be less likely to buy plug-ins unless recharging infrastructure is developed. Electrical outlets or charging stations near their places of residence, or in commercial or public parking lots or streets or workplaces are required for these potential users to gain the full advantage of PHEVs. Even house dwellers might need to charge at the office or to take advantage of opportunity charging at shopping centers. However, this infrastructure is not in place today and it will require investments by both the private and public sectors.

Several cities in California and Oregon, and particularly San Francisco and other cities in the San Francisco Bay Area and

Silicon Valley, as well as some local private firms such as Google and Adobe Systems, already have deployed charging stations and have expansion plans to attend both plug-ins and all-electric cars. In Google's case, its Mountain View campus has 100 available charging stations for its share-use fleet of converted plug-ins available to its employees. Solar panels are used to generate the electricity, and this pilot program is being monitored on a daily basis and performance results are published in RechargeIT website.

Emissions shifted to electric plants

Increased pollution is expected to occur in some areas with the adoption of PHEVs, but most areas will experience a decrease. A study by the ACEEE predicts that widespread PHEV use in heavily coal-dependent areas would result in an increase in local net sulfur dioxide and mercury emissions, given emissions levels from most coal plants currently supplying power to the grid. Although clean coal technologies could create power plants which supply grid power from coal without emitting significant amounts of such pollutants, the higher cost of the application of these technologies may increase the price of coal-generated electricity. The net effect on pollution is dependent on the fuel source of the electrical grid (fossil or renewable, for example) and the pollution profile of the power plants themselves. Identifying, regulating and upgrading single point pollution source such as a power plant—or replacing a plant altogether—may also be more practical. From a human health perspective, shifting pollution away from large urban areas may be considered a significant advantage.

Tiered rate structure for electric bills

Electric utility companies generally do not utilize flat rate pricing. For example, Pacific Gas and Electric (PG&E) normally charges $0.10 per kilowatt hour (kW·h) for the base tier, but additional tiers are priced as high as $0.30 per kW·h to customers without electric vehicles. Some utilities offer electric vehicle users a rate tariff that provides discounts for off-peak usage, such as overnight recharging. PG&E offers a special, discounted rate for plug-in and other electric vehicle customers, the "Experimental Time-of-Use Low Emission Vehicle rate." That tariff gives people much cheaper rates if they charge at night, especially during the summer months.

The additional electrical utilization required to recharge the plug-in vehicles could push many households in areas that do not have off-peak tariffs into the higher priced tier and negate financial benefits. Without an off-peak charging tariff, one study of a certain PHEV-20 model having an all-electric range of 20 miles, gasoline-fueled efficiency of 52.7 mi/gal U.S., and all-electric efficiency of 4 mi/kW·h, found that household electricity customers who consumed 131%–200% of baseline electricity at $0.220/(kW·h) would see benefits if gasoline was priced above US$2.89/US gal; those that consumed 201%–300% of baseline electricity at $0.303/(kW·h) would only see benefits if gas was priced above $3.98; and households consuming over 300% of baseline electricity at $0.346/(kW·h) would only see benefits if gasoline was priced above $4.55 (USD/gal). Off-peak tariff rates can lower the break-even point. The PG&E tariff would change those break-even gasoline prices to USD $1.96, $3.17 and $3.80 per gallon, respectively, for the given PHEV and usage pattern in question.

Customers under such tariffs could see significant savings by being careful about when the vehicle was charged, for example, by using a timer to restrict charging to off-peak hours. Thus, an accurate comparison of the benefit requires each household to evaluate its current electrical usage tier and tariffs weighed against the cost of gasoline and the actual observed operational cost of electric mode vehicle operation.

Lithium availability and supply security

Current technology for plug-ins is based on the lithium-ion battery and an electric motor, and the demand for lithium, heavy metals and other rare elements (such as neodymium, boron and cobalt) required for the batteries and powertrain is

expected to grow significantly due to the incoming market entrance of plug-ins and electric vehicles in the mid and long term. Some of the largest world reserves of lithium and other rare metals are located in countries with strong resource nationalism, unstable governments or hostile to U.S. interests, raising concerns about the risk of replacing dependence on foreign oil with a new dependence on hostile countries to supply strategic materials.

Currently, the main deposits of lithium are found in China and South America throughout the Andes mountain chain. In 2008 Chile was the leading lithium metal producer, followed by Australia, China, and Argentina. In the United States lithium is recovered from brine pools in Nevada. Nearly half the world's known reserves are located in Bolivia, and according to the US Geological Survey, Bolivia's Salar de Uyuni desert has 5.4 million tons of lithium, which can be used to make lithium batteries for hybrid and electric vehicles. Other important reserves are located in Chile, China, and Brazil. Regarding rare earth elements, most reserves are located in China, which controls the world market for these elements.

Production and commercialization

A survey from Pike Research shows 22% of 1,041 consumers extremely and 26% very interested in buying a PHEV-40-(like the Volt), with 17% willing to pay 20–50% more than a standard vehicle and half willing to pay 5-10% more. Another 34% have some interest for a total of 82%. Pike projects 1.7 million PHEVs on the world's roads by 2015 and half a million annual sales.

Current production models

The BYD F3DM became the world's first mass produced plug-in hybrid compact sedan as it went on sale in China to

Launched in December 2008, the BYD F3DM became the world's first mass produced plug-in hybrid automobile. |

government agencies and corporations on December 15, 2008. Sales to the general public began in Shenzhen in March 2010 but because the F3DM nearly doubles the price of cars that run on conventional fuel, BYD Auto is counting on subsidies from the local government to make the plug-in attractive to personal buyers. The F3DM is sold for 149,800 yuan (about USD 21,900), and during its first year in the market the F3DM only sold 48 vehicles. The F3DM has a all-electric range of 100 kilometers (60 mi), and is slated to go on sale in Europe and the U.S. in 2011.

In the United States, the Toyota Prius can now be commercially converted (using aftermarket kits and tax incentives) to a plug-in hybrid by CalCars and a number of third-party companies.

On a smaller scale, PHEVs have been sold as commercial passenger vans, utility trucks, general and school buses, motorcycles, scooters, and military vehicles. Hybrid Electric Vehicle Technologies, Inc converts diesel buses to plug-in hybrids, under contract for the Chicago Transit Authority. Fisker Coachworks is developing a plug-in hybrid, the Fisker GTB-40, which is expected to get about twice the mileage of a regular hybrid electric bus.

Future production

At least fourteen car companies of all sizes are exploring or planning to offer a plug-in, including a modular kit car model (XR-3 Hybrid). General Motors is planning to sell a PHEV version of the Chevrolet Volt, which will have an electric range of 40 miles (64 km), in 2010. The Envi division of Chrysler has announced five different electric models, with one expected to be for sale by 2010, and three by 2013.

A startup in California named Aptera Motors is creating a series drivetrain PHEV version of its concept electric car, the Aptera 2h.

The PHEV Toyota Prius will be offered beginning with commercial fleets in 2009. The Prius PHEV version will be powered by lithium-ion batteries. Nikkei news reported that Toyota will start series production of the Prius PHEV version in 2012, and the estimated price is USD48,000. Battery-only range and other operational details will not be known until 2010, based on the performance of the 500 prototypes that will be available for fleet buyers beginning in late 2009.

The luxury Fisker Karma PHEV-50 (PHEV80 km) sports car is slated for late 2009, and the Volkswagen Golf PHEV-50 km plug-ins are expected in 2010. Volvo's diesel plug-in and Ford's PHEV-30 Escape SUV, already being used in utility fleets, are scheduled to be available to the general public in 2012.

Conversion kits and services are available to convert production model hybrid vehicles to plug-ins.

NiMH battery patent encumbrance

Some battery formats and chemistries (nickel-metal hydride batteries) suitable for use in PHEVs are tightly patented and have not been licensed for use by PHEV manufacturers, thereby slowing the development of electric cars and PHEVs, particularly before the 2008 Oil Crisis.